Changing Shipping Practices

Many business owners continued to use the railroad to ship their products. But the trucking of goods meant products to regional and national markets.Featuring:Dora Giese, (1919 – 1983), Beich candy workerArthur Johnson, (1901 – 1952), washing machine assembly workerRoy Yanney, (1896 – 1969), Williams Oil-O-Matic factory workerBeich Candy Company

Dora Giese (1919-1983) began working for Beich Candy Company in 1934 at the age of 15. She made one cent for every 24 candy bars she wrapped and packed into a box. Dora and other workers walked to the plant each morning just to see if they had work that day. Floor managers selected their work force daily, depending on who was at the factory gate.

Soon after being hired, Dora discovered that one manager only called in workers who brought her eggs, butter, or coal.

How would you feel about such favoritism? What could you do about it?

In early April 1937 Dora was among the workers who organized the Bakery, Confectionery & Tobacco Workers Local 342 (BC&T). On April 23 the union went to company leaders asking for better pay, including less disparity between the pay for men and women doing the same work, and hourly wages instead of piecework (by the quantity) pay. They were told to wait until May 4, when company owner Otto Beich would return from a meeting.

When management extended work hours the following Monday (April 26), workers feared the company was stocking the warehouse against a future strike.

Already working six-day weeks, union members decided not to work on April 29. Instead they picketed peacefully until May 4 when they began negotiations.

On May 13 an agreement was reached, which included pay raises, a 40-hour work week, and a closed shop. This meant Beich’s would only hire union members and workers had to remain members of their specific union to be employed.

The strike continued through January 1938 with all new offers rejected because they included an open shop. But on February 3, an agreement was reached that included the BC&T No. 342 as the sole bargaining agent for all workers employed in the manufacturing of candy at Beich’s.

Dora worked packing candy for Beich’s for 49 years, retiring in 1983.

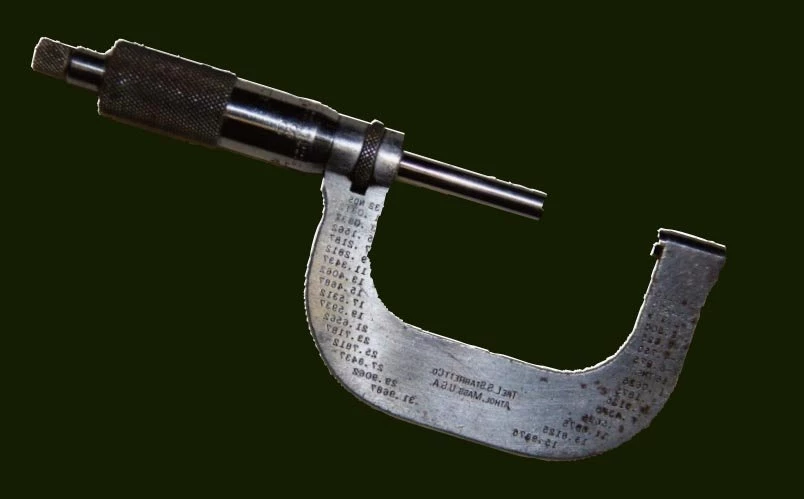

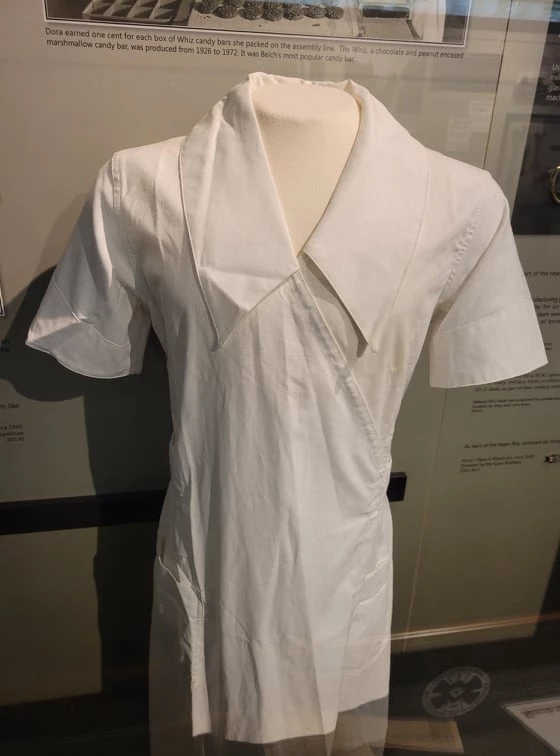

Beich candy maker's uniform, circa 1945

View this object in Matterport

Dora and all other female line workers at the Beich factory were required to wear a uniform like this one, which belonged to Beich factory worker Ann Sheppelman.

Donated by: Ann Sheppelman

2001.65

Arthur Johnson

Arthur Johnson (1901-1952) got his first job shortly after he finished eighth grade, working in the bindery at Pantagraph Printing and Stationery. But he decided that a machinist apprenticeship at the C&A shops was a better option and would keep him out of the coal mine where his father worked.

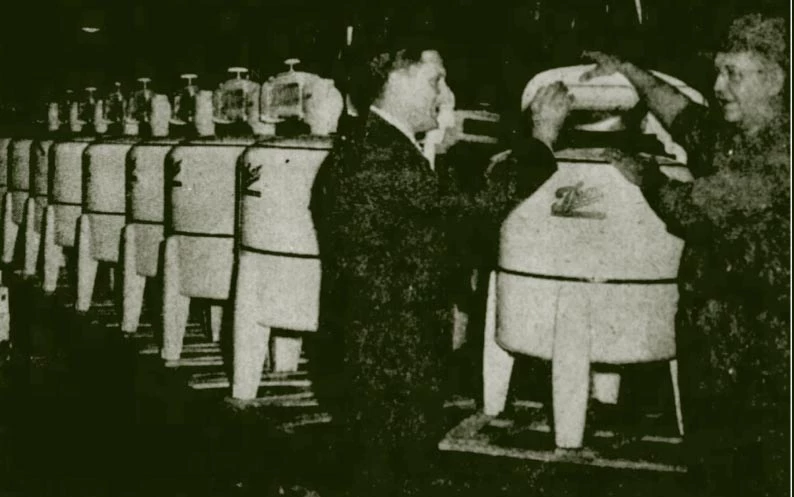

At the shops Art learned how to use a lathe, milling machines, and grinders to produce precision metal parts to be used for railroad engines and cars. In 1922, soon after he had completed his apprenticeship, he took the skills he learned to the Meadows factory where he got a job making washing machines.

In 1946, after 24 years of making and repairing parts for the company’s assembly line, Art was put in charge of the line. Workers on the line depended on him to make sure the equipment was running well and that the timing was just right so they could do their work efficiently. As a result, the company produced 65,000 wash machines that year.

By October 30 of the following year, the plant had produced 100,000 units, or about 600 machines per day. Aware that they were setting a record, the union asked Meadows to donate the 100,000th machine to the union. It was given to a lucky member at the plant Christmas party that year.

Art was still working for Meadows when he died in 1952.

Meadows wash machine, circa 1950

View this object in Matterport

Donated by: Kathleen Tipton

2000.55.2

Williams Oil-O-Matic

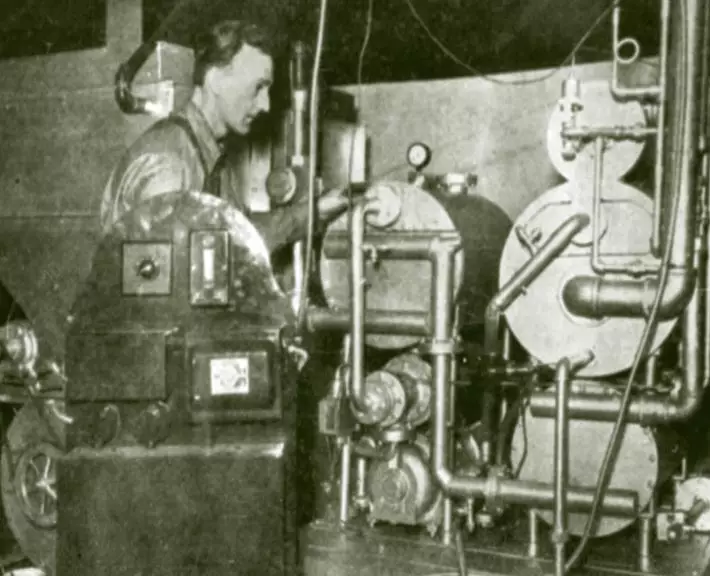

Roy Yanney (1896-1969) worked as a farmer both before and after serving as an ordnance worker in the Army during World War I. But he left the farm to work as a mechanic at Williams Oil-O-Matic when the company opened their first factory in 1924. There Roy helped maintain and repair the equipment used to manufacture oil heaters.

In 1928, when the company began to develop and manufacture refrigerators, water heaters, and milk coolers, Roy was involved with the testing of new units and later their assembly. He was also involved in the development of a combination heating and air conditioning (HVAC) unit for homes and businesses in 1936.

When the U.S. became involved in WWII, Roy and his coworkers retooled areas of the shop for war production, and he became a machinist.

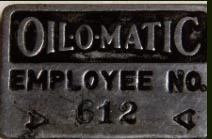

Using lathes, milling machines, and grinders, Roy produced precision metal components for military use. He would have used a micrometer, like this one, to ensure precise measurements. He wore safety glasses, like these used by Frank Moews — a required saftey precaution for all workers in the machine shop.

Roy was part of the team that earned a Navy E Award for Williams Oil-O-Matic.

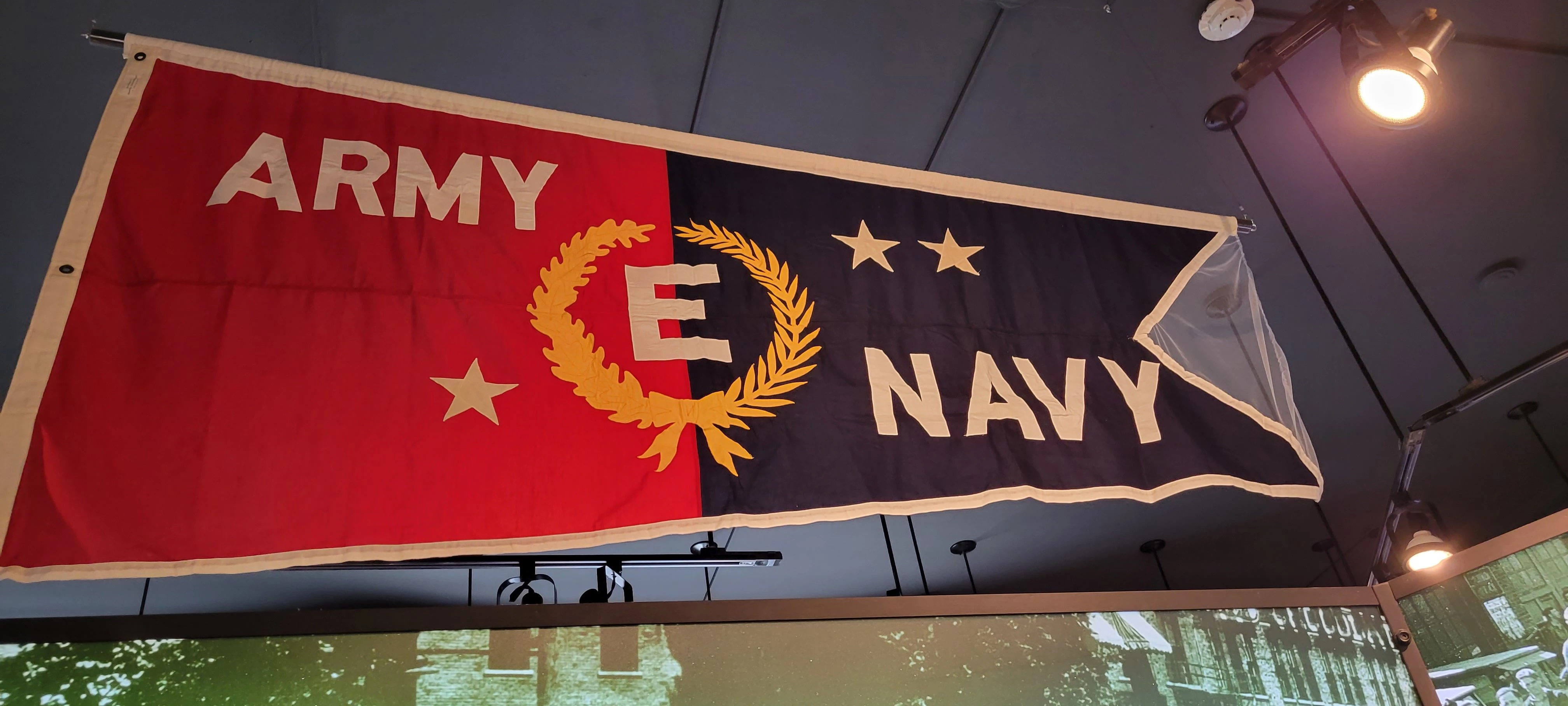

Army / Navy E Flag, circa 1943

View this object in Matterport

Companies manufacturing products for the millitary with excellent output and quality for six months were awarded an Army / Navy E (for excellence) flag. More stars were added to the flag for additional six-month periods of excellence. Williams Oil-O-Matic received five stars.

Donated by: Electrolux Corporation

2011.056.01

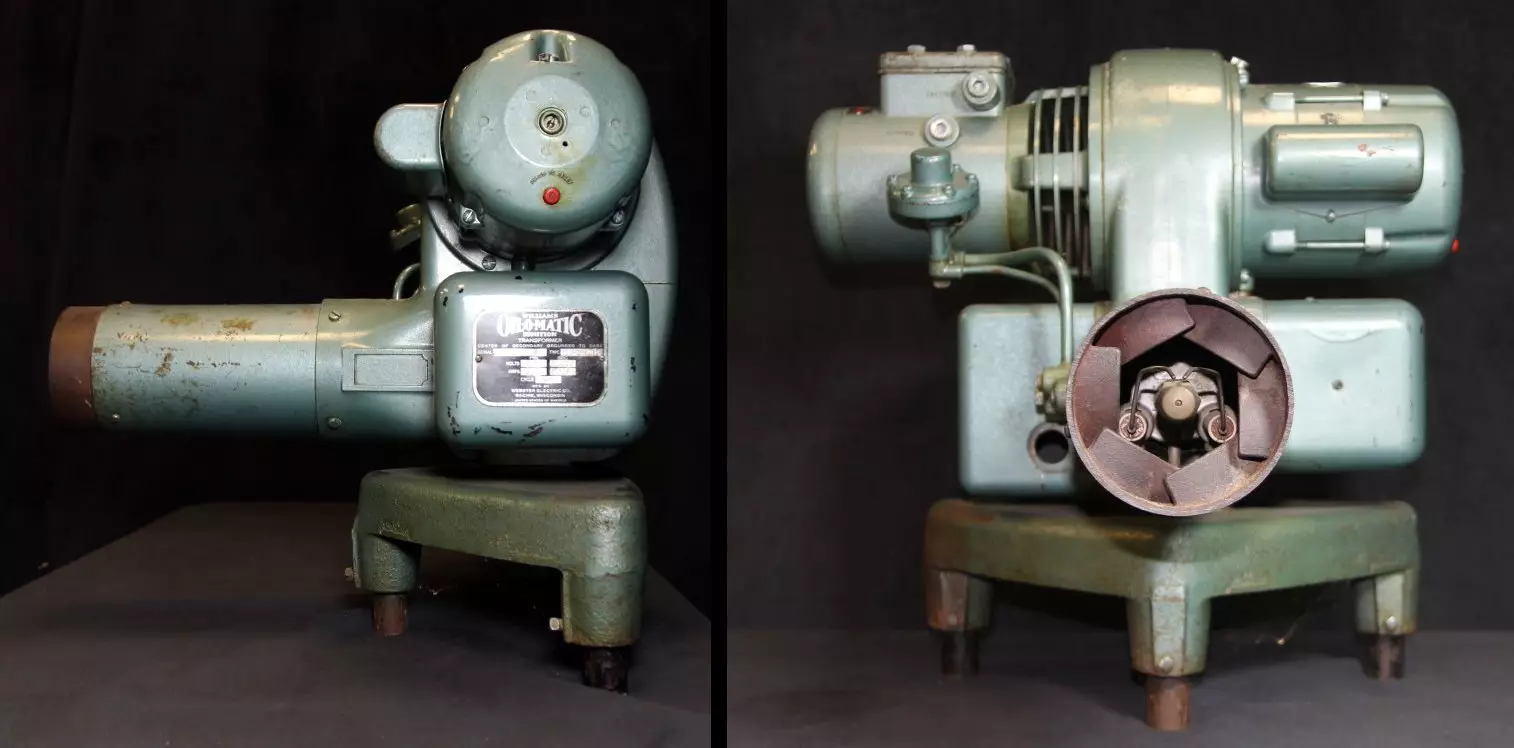

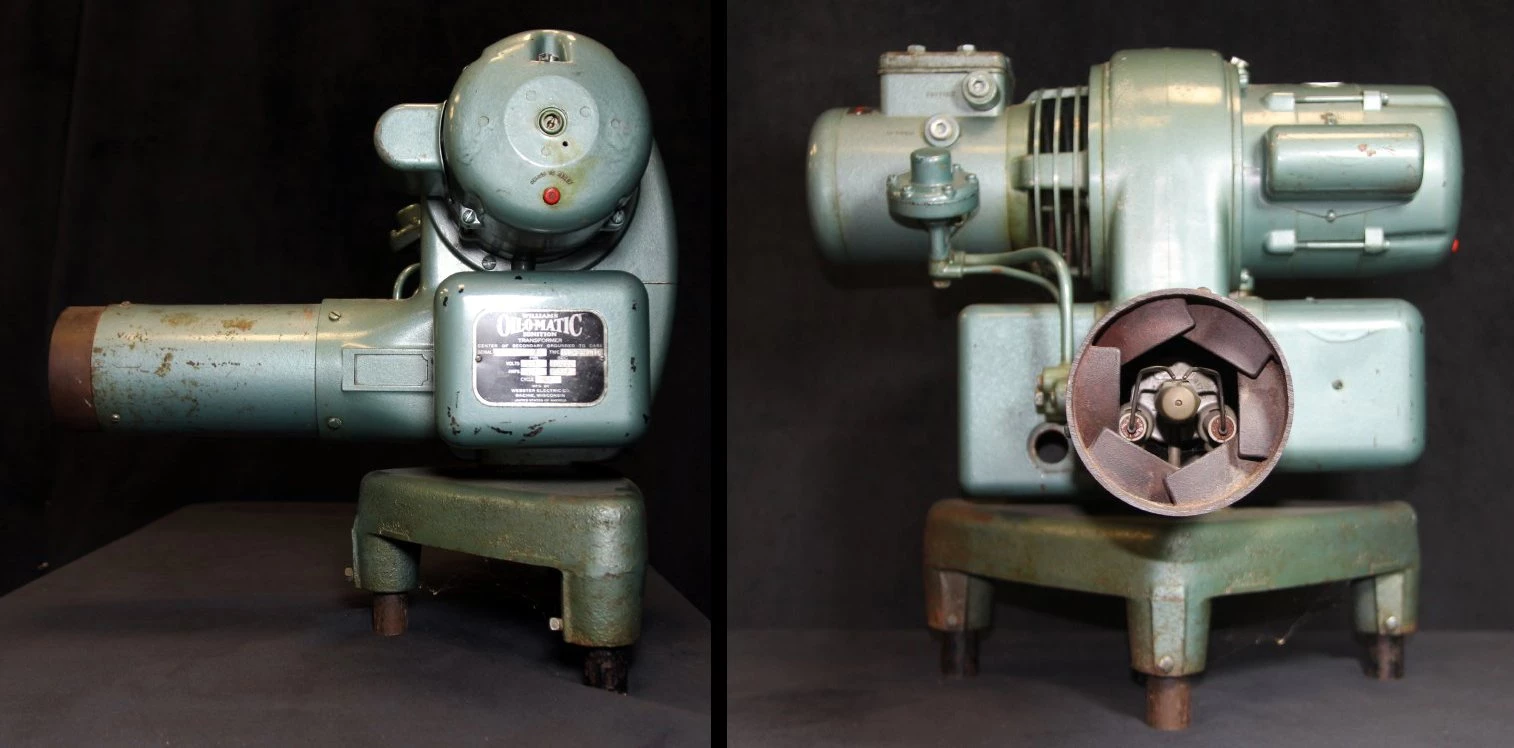

Williams Oil-O-Matic heater, circa 1948

View this object in Matterport

When Roy started at Williams, he was on the production line of the new Oil-O-Matic heater. It was developed by Walter Williams when a coal shortage made it hard to heat the Williams & Son East Washington Street auto dealership and garage. The unit was fueled with used automobile oil.

Donated by: Bill and Jeane Matheson

99.30

Making a Home

Making a Home

A Community in Conflict

A Community in Conflict

Working for a Living

Working for a Living

Farming in the Great Corn Belt

Farming in the Great Corn Belt

Abraham Lincoln in McLean County

Abraham Lincoln in McLean County