Providing for a Regional Market

Thanks to the ease of railroad shipping, many local manufacturers were able to sell their goods beyond McLean County.Featuring:Arnold Reigger, (1831 – 1913), Stove pattern makerRichard Allen, (1832 – 1899), stove assemblerGeorge A. Tay, (1842 – 1916), trunk builderMamie Delaney, (1864 – 1932), seamstress at Klemm’s Shirt & Overall FactoryBerthold “Bert” Embach, (1835 – 1879), Meyer Brewing Company laborerArnold Reigger

German immigrant Arnold Reigger (1831-1913) was hired by the Bloomington Stove Company in 1875. A pattern maker, the company could not make stoves without workers with his skill.

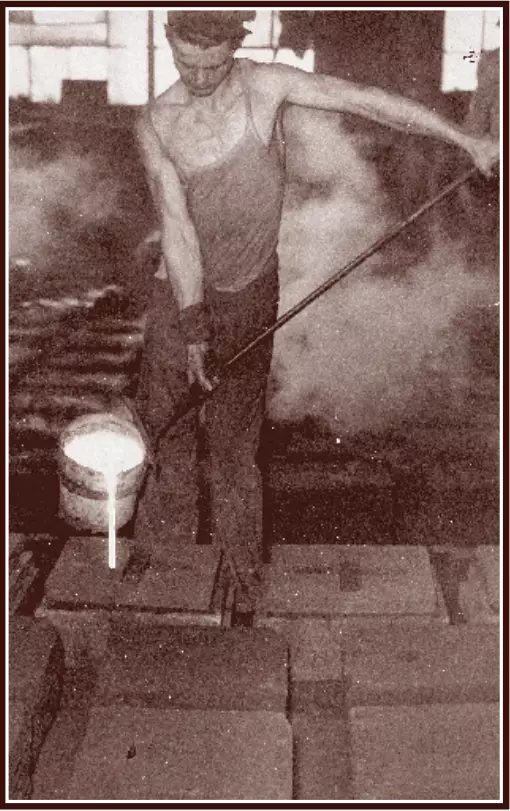

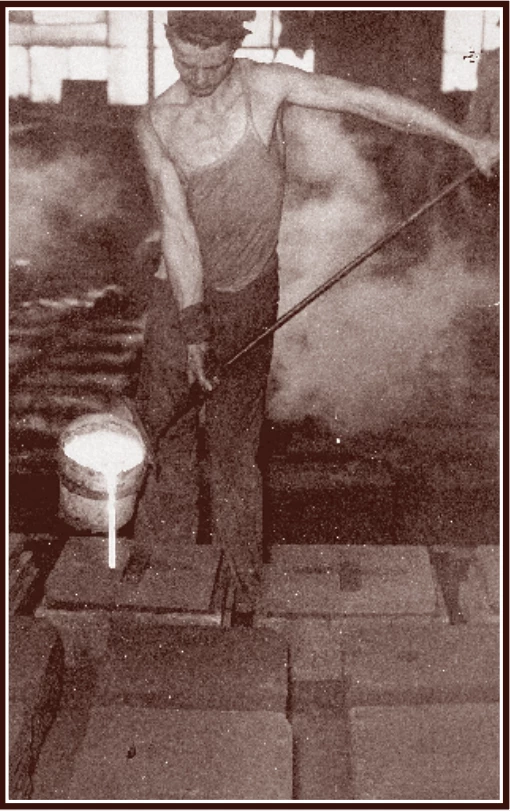

Arnold hand-carved full-scale wooden patterns used for creating stove parts.

These patterns were used to press a shape into a mold filled with a special compressed sand. When the pattern was removed, it left a void the shape of the item to be cast. The two parts of the mold were then put together by laborers working in the foundry, who heated and then poured molten metal into the void. When the metal cooled, the part was removed, cleaned, and assembled with other parts.

Richard Allen

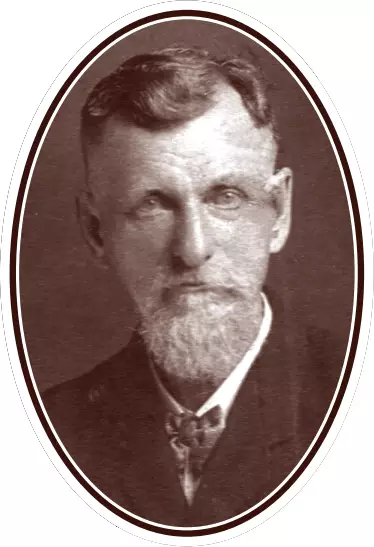

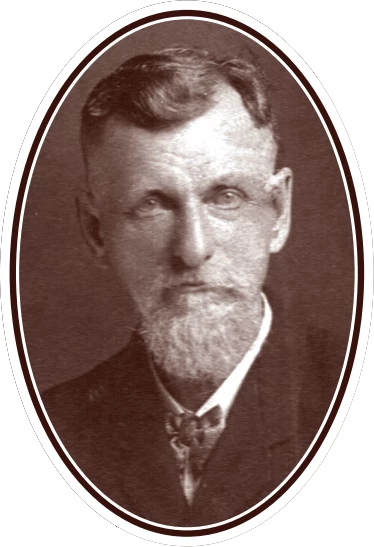

The son of Irish immigrants, Richard Allen (1832-1899) arrived in Bloomington and found work as a mounter for the Bloomington Stove Company shortly after it was founded in 1869.

Richard’s job was simple — to secure parts of the stove together with nuts and bolts using screwdrivers and pliers.

Richard’s job was steady, but assembling the same parts together day after day could be monotonous.

Would you like this type of work?

Do you think Richard stayed at the stove company, or moved on?

Richard appreciated the regular paycheck and appeared not to mind the repetition of his job, as he continued to work as a stove mounter until his death in 1899 at the age of 67.

The Bloomington Stove Company produced parlor stoves, like the one displayed here, which were used for heating the home. They also produced cook stoves, like the Grand Central cook stove pictured above, which were used for cooking meals. Both of these stoves used wood as fuel and were essential to the home in the early 1900s. Without them the only source of heat or place to cook in a home was the fireplace.

In 1885 Richard and his coworkers assembled 173 different sizes and styles of cooking and heating stoves.

George A. Tay

George A. Tay (1842-1916) was a trunk builder in Chicago. But after his business was destroyed by the Great Chicago Fire of 1871, he moved to Bloomington where he reestablished his business in the spring of 1872.

George built flat-topped trunks, as well as domed trunks, at his factory. He also did a brisk business, both wholesale and retail, in satchels and suitcases.

All his products began with the construction of a pine box and lid. Next George covered the box with decorative paper, leather, canvas, and / or tin. Metal strapping and corners, secured with nails, were added to strengthen the box. Handles, locks, and hinges were also added.

Trunk interiors were covered with printed paper. More complex trunks included drawers, removable trays, and compartments that made organizing the contents of a trunk easier.

By 1878 George had hired additional workers to meet demand for his products. That year he added brushes to the list of items manufactured in his factory and changed the name of the business to the Bloomington Brush and Trunk Company.

George liked building trunks, but soon tired of managing the financial side of the business.

He had options:

He could hire and manage people to do the bookkeeping, marketing, and sales;

He could sell the business, but continue to work there;

He could sell the business and leave.

What choice do you think George made?

George sold his business to L.C. Tonnies and August Boeker in 1881, but continued to manage the manufacturing end of the business until he retired in 1889.

Women’s jobs, whether manufacturing or service, reflected domestic expectations.

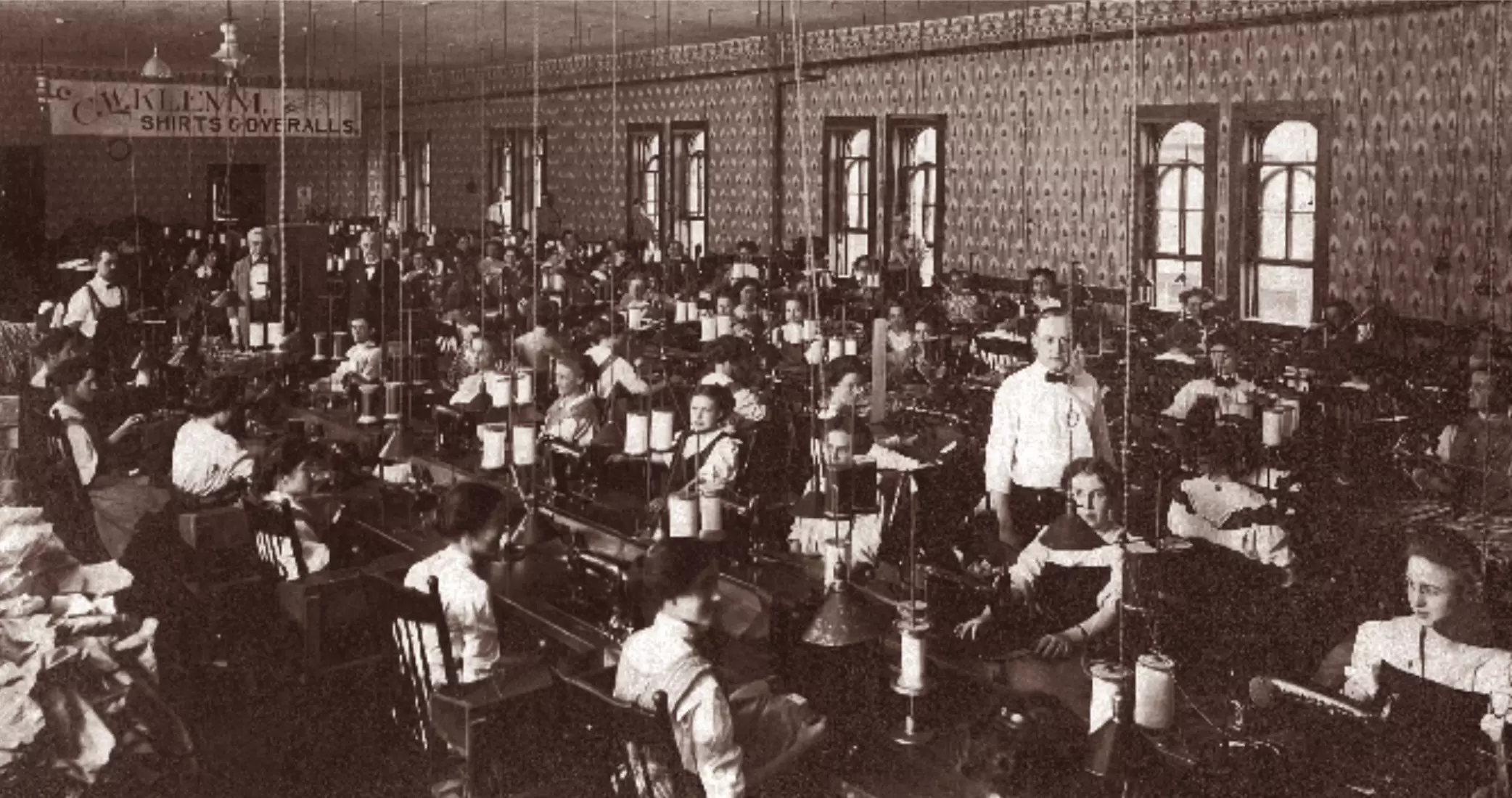

Mamie Delaney (1864-1932) spent 32 years sewing garments at Klemm’s Shirt & Overall Factory.

She sat at a sewing machine where she stitched together a specific piece of the garment, before passing it on to the next stitcher.

The assembly-line approach was repetitive, but it meant the final product was completed more quickly and with greater consistency.

In 1915 Mamie and 79 other sewers moved from the old factory in the Hoopes building on the northeast corner of Monroe and Center streets, to a new five-story factory at 312-314 N. Center Street.

She and her coworkers were pleased with the modern new ladies’ restroom and special lunchroom where they were provided with free coffee and hot chocolate.

It’s no wonder Mamie and others worked for Klemm’s for many years. The owner, Carl W. Klemm, had a reputation for treating his workers like family.

Mamie was still employed at the Klemm’s factory when she died in 1932.

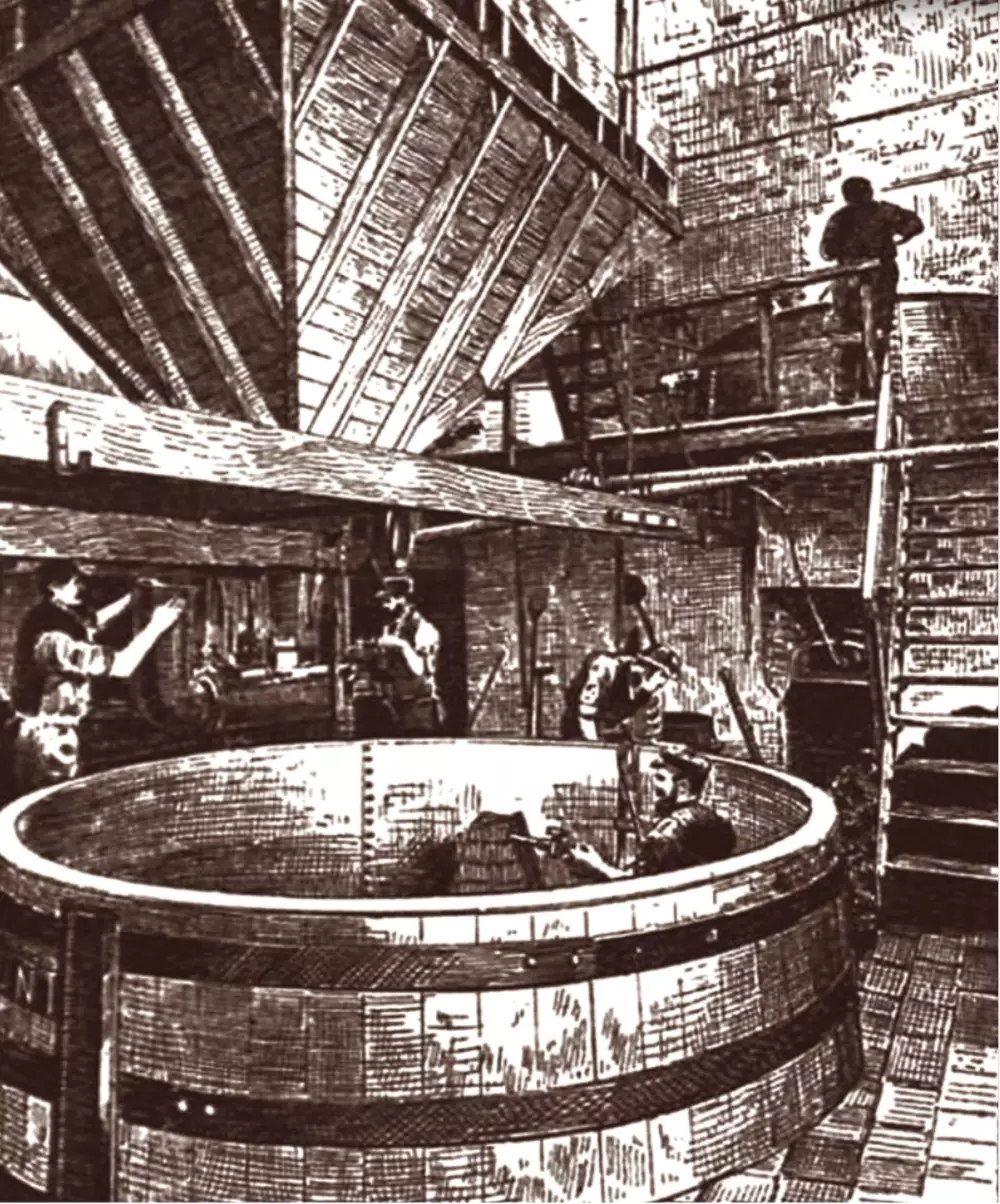

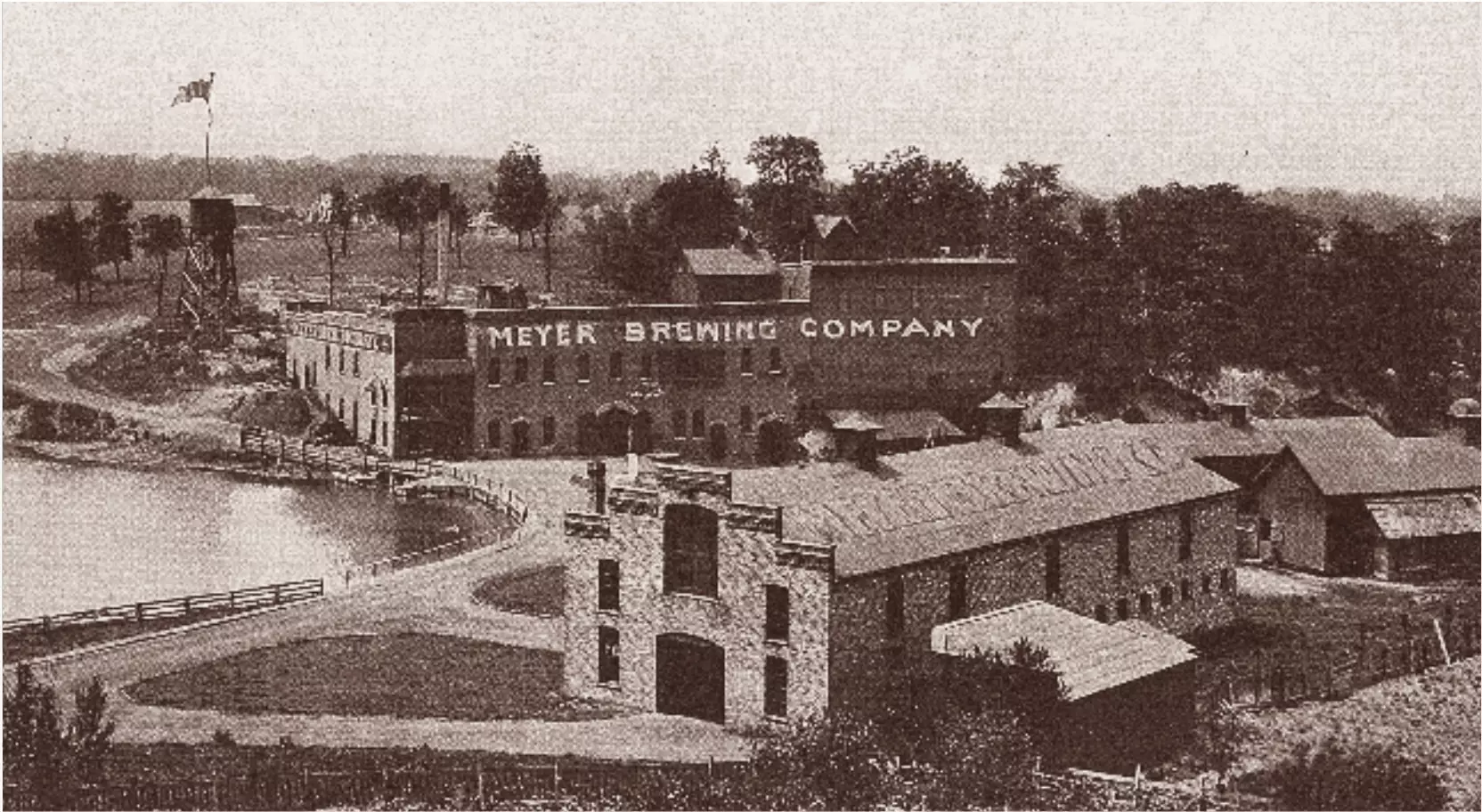

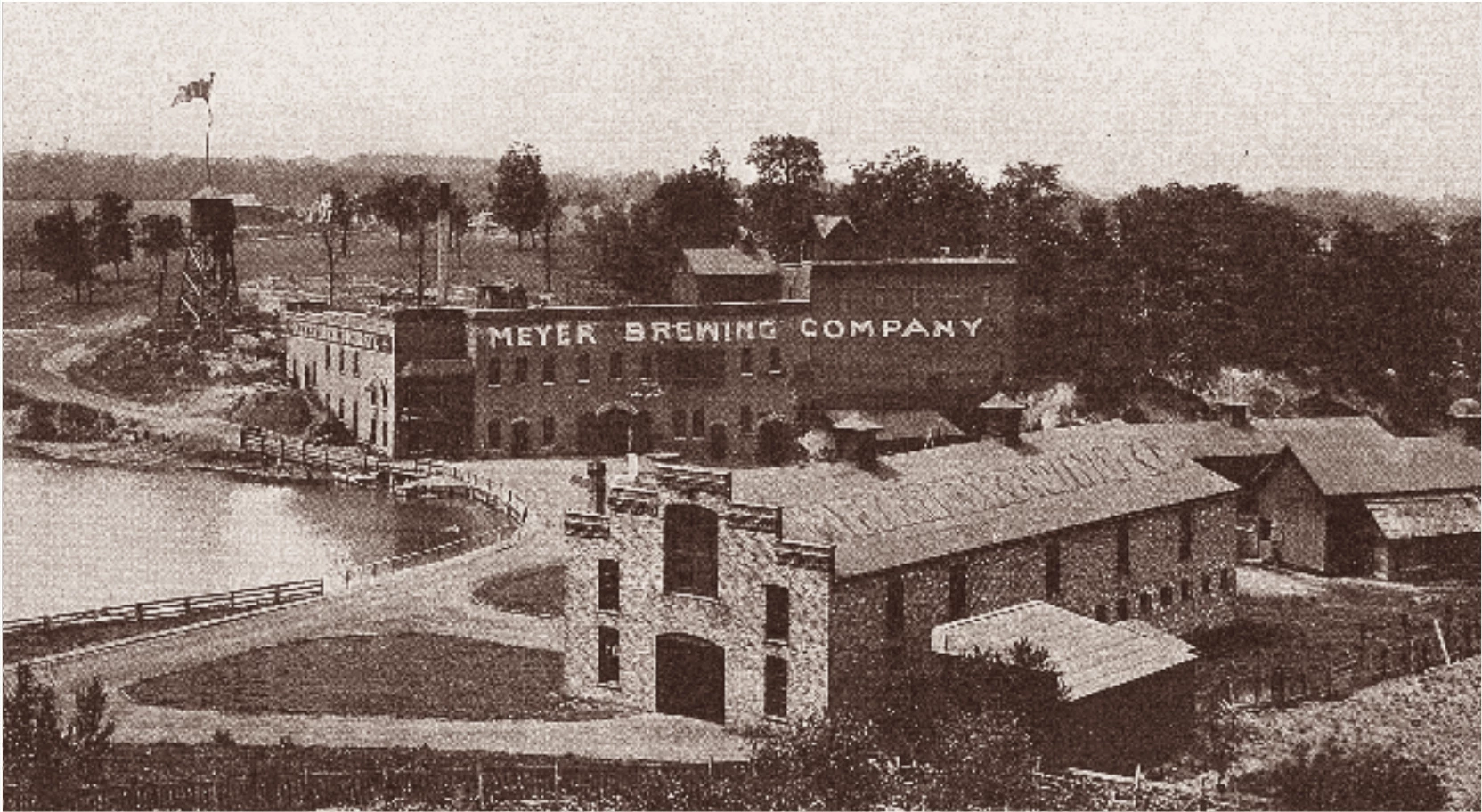

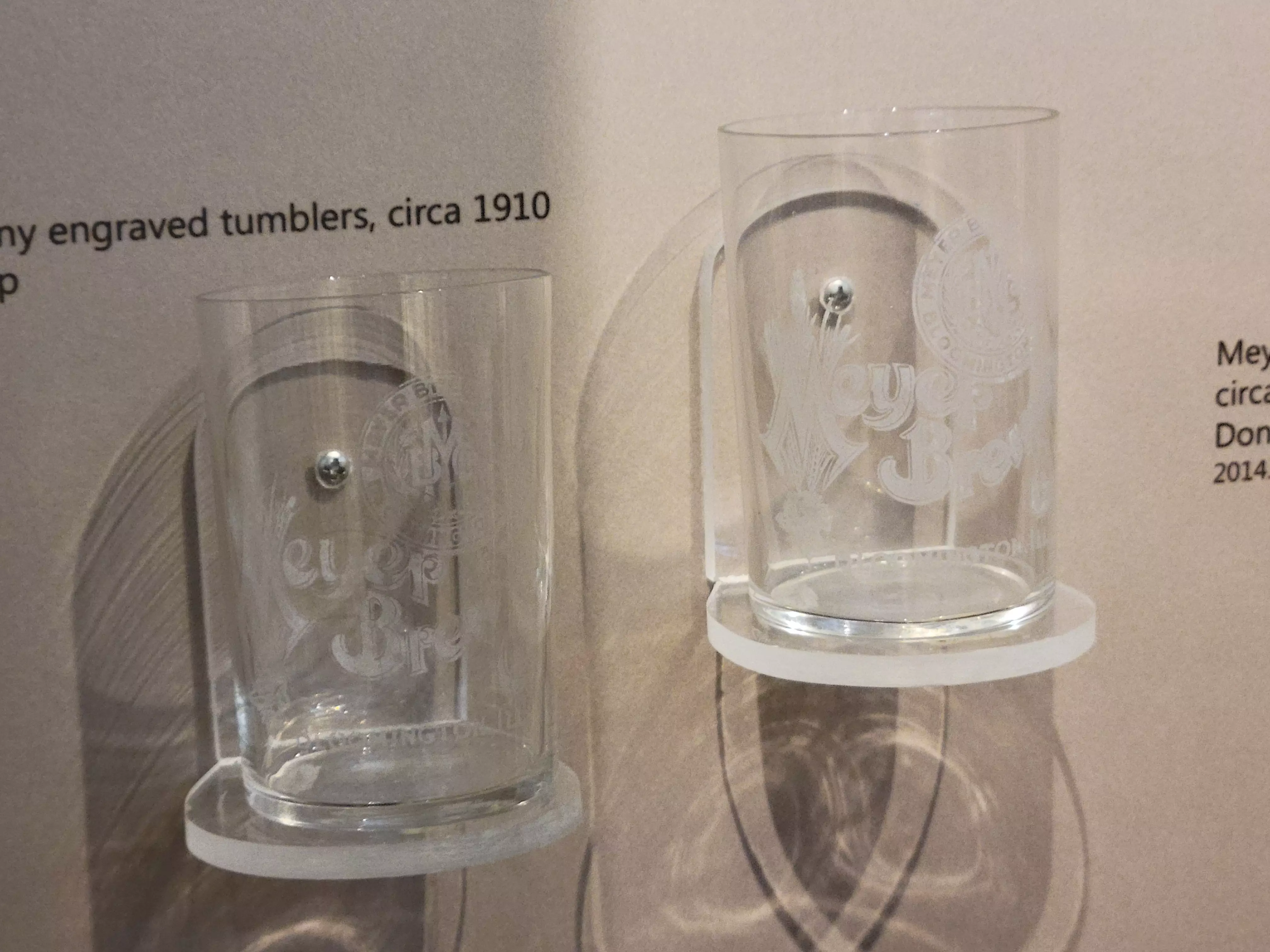

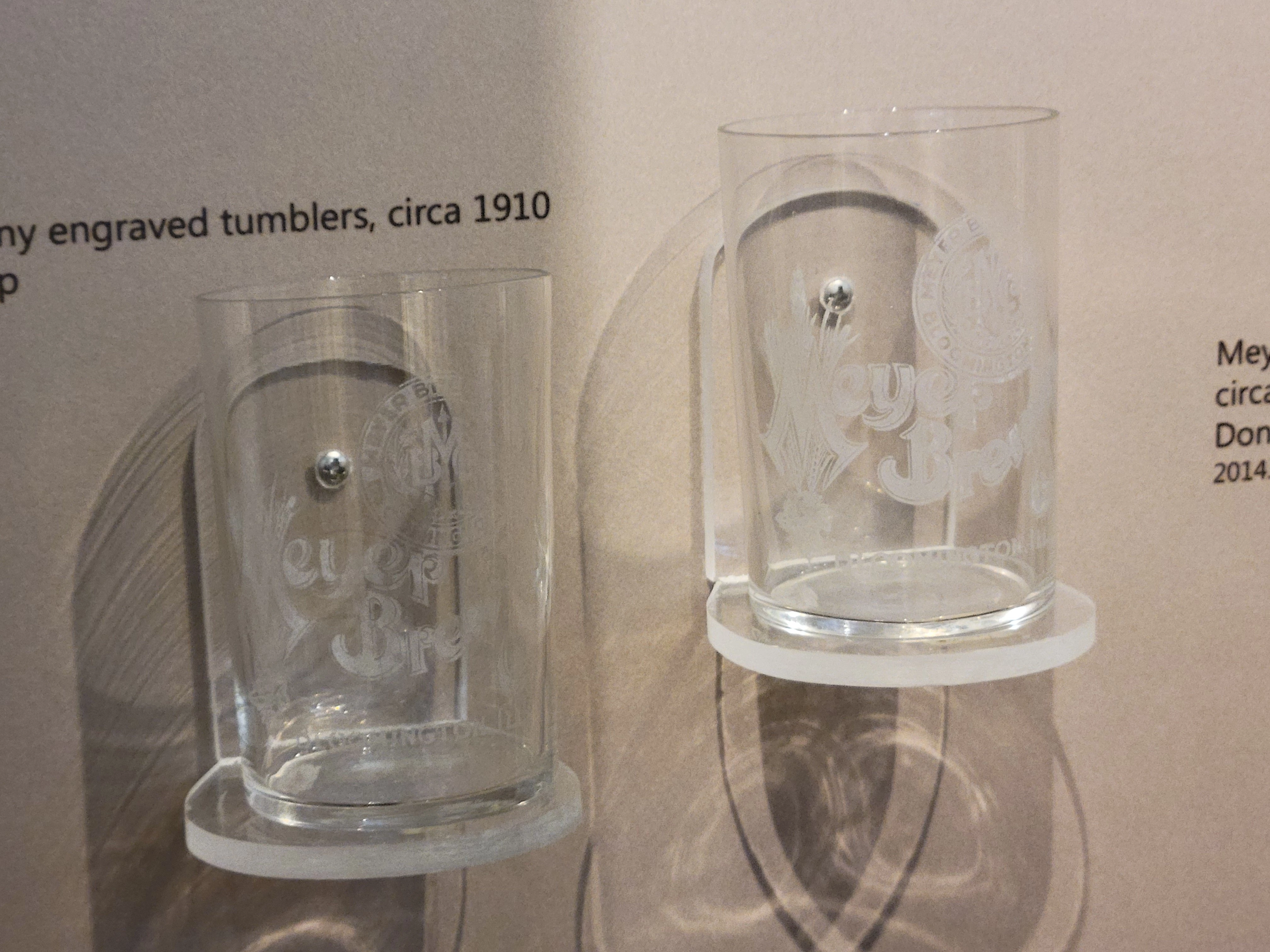

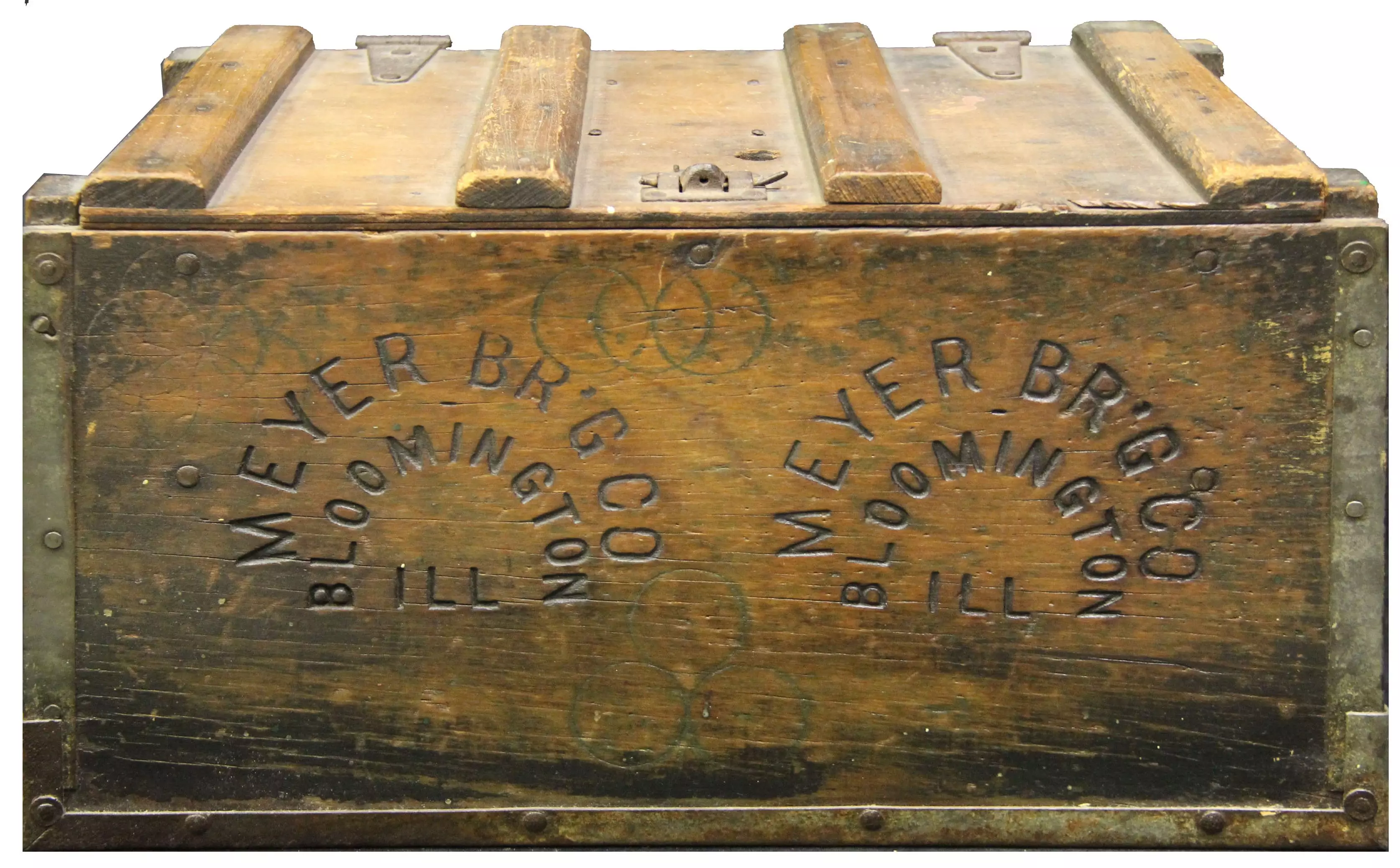

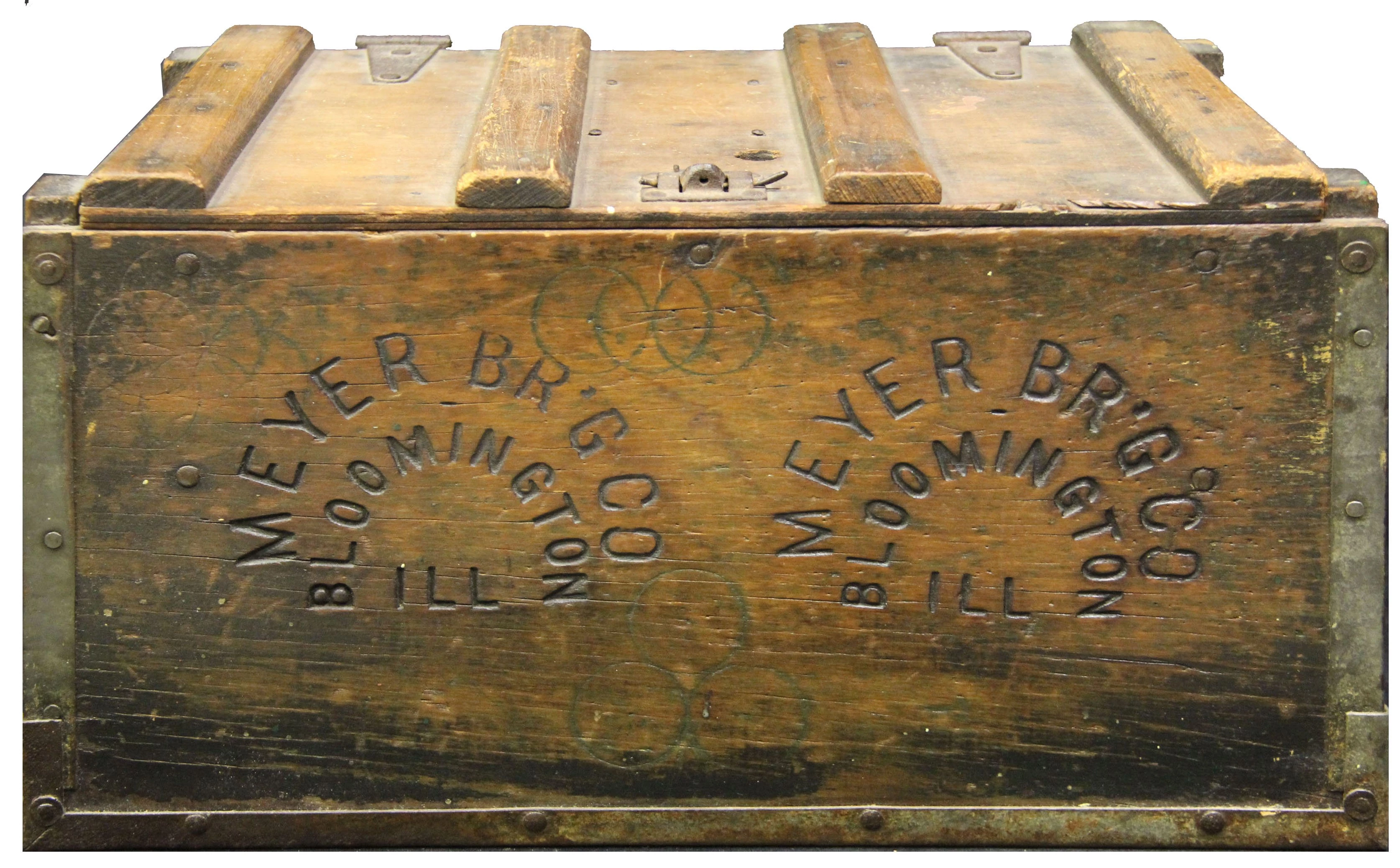

Berthold “Bert” Embach (1835-1879) immigrated to the U.S. from Baden, Germany in 1855 and became a naturalized citizen in 1860. When fellow German immigrants Anthony Meyer and Francis Wochner started the Meyer Brewing Company south of Bloomington in 1862, Bert was asked to join them.

Bert hauled water, helped make mash, scrubbed the mash tanks, and whatever else needed to be done to help the brew master. He continued to do this job until 1879 when he died at the age of 44.

Bloomington restricted the sale of alcoholic beverages for six months in 1874. Forty years later, in 1914, residents voted to outlaw the sale and consumption of alcohol. This temporary prohibition was repealed in 1916, but two years later residents voted to go “dry” again.

How do you think these changing laws and attitudes afffected the brewery and its employees?

Each of these events challenged the continued success of Meyer’s brewery. Local business ceased during these periods, but production continued for regional markets (most likely with fewer employees). It was the National Prohibition Act of 1919 (also known as the Volstead Act), which prohibited the production, sale, and transportation of non-medicinal alcohol nationwide, that finally forced the Meyer Brewing Company to close in 1920.

Making a Home

Making a Home

A Community in Conflict

A Community in Conflict

Working for a Living

Working for a Living

Farming in the Great Corn Belt

Farming in the Great Corn Belt

Abraham Lincoln in McLean County

Abraham Lincoln in McLean County