Crafting Custom Products for a Local Market

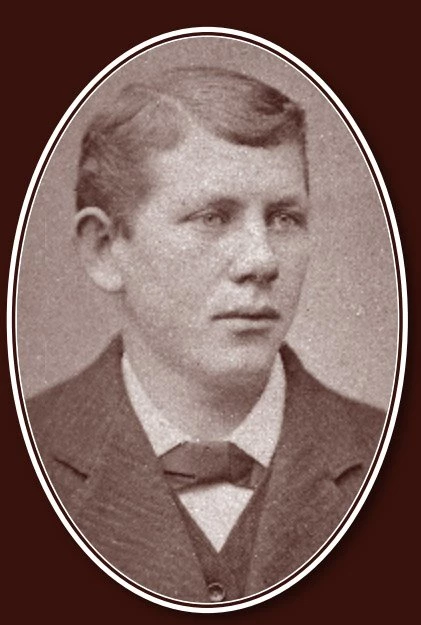

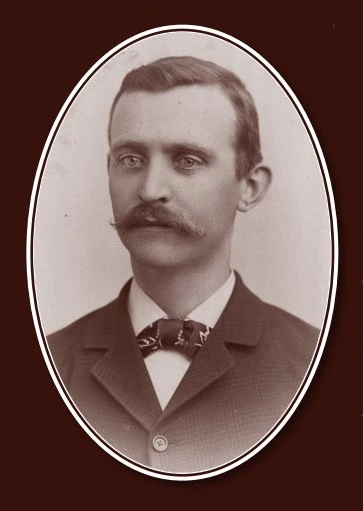

Skilled craftsmen set up shops and began to produce one of a kind items for the local market. They often hired apprentices who learned the trade on the job.Featuring:Charles A. Kleinau, (1858 – 1933), stone cutterCharles Gmehlin, (1834 – 1914), gunsmithMary J. Megowen Keith, dressmakerGustave A. Wohlfeil, tailorChrist Mandler, (1858 – 1949), cigar makerGerman immigrant Charles A. Kleinau (1858-1933) was six years old when he arrived in the U.S. As a teen he spent a few months laboring for Peter Greenwald, one of Bloomington’s first stonecutters. The experience convinced him that stonecutting was a trade he wanted to pursue.

In 1878 Charles began as a laborer for Higgins & Company in exchange for on-the-job training. Under the tutelage of Hamer Higgins, he learned the skills needed to cut stone to be used for building structures, as well as to carve headstones complete with decorative elements.

In 1890 Charles and fellow stonecutter Jacob Jung became partners in the business, which was renamed Higgins, Jung, and Kleinau.

A stonecutter for life, Charles was vice president of the company when he died in 1933.

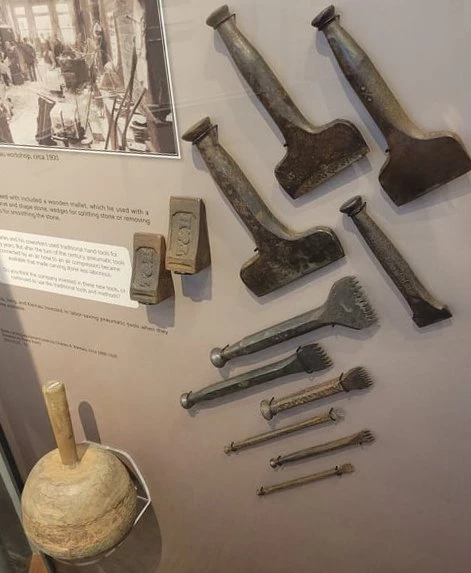

The tools Charles worked with included a wooden mallet, which he used with a variety of chisels to carve and shape stone, wedges for splitting stone or removing large pieces, and files for smoothing the stone.

Charles and his coworkers used traditional hand tools for many years. But after the turn of the century, pneumatic tools (connected by an air hose to an air compressor) became available that made carving stone less laborious.

Do you think the company invested in these new tools, or continued to use the traditional tools and methods?

Higgins, Jung, and Kleinau invested in labor-saving pneumatic tools when they became available.

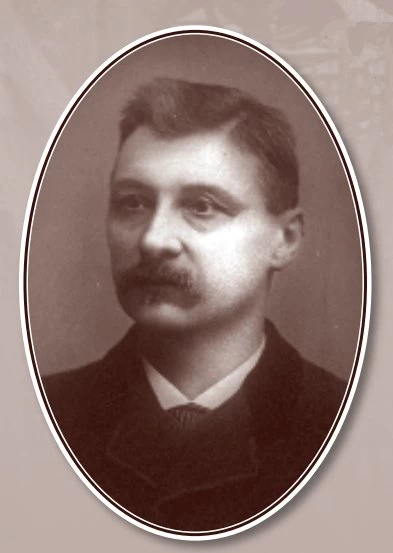

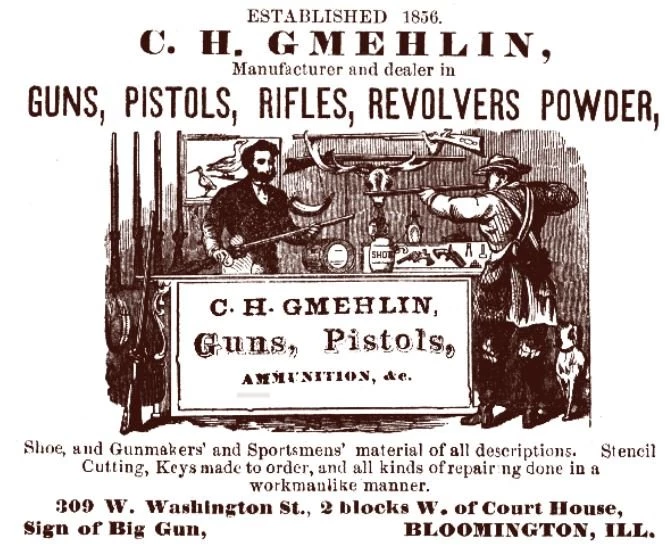

Charles Gmehlin

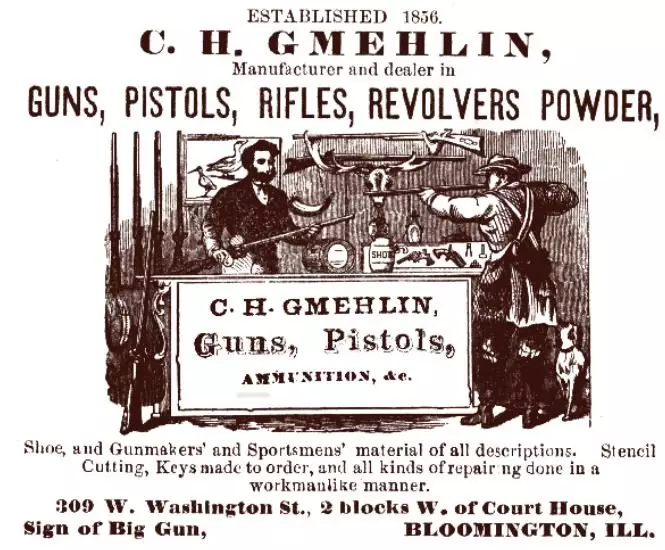

Charles Gmehlin (1834–1914) was a successful gunsmith who learned the trade in Germany and gained experience in France, England, and Switzerland before coming to the United States and making his home in Bloomington in 1857. He established a gun shop where he crafted and repaired shotguns, rifles, and pistols.

With his many skills, including machining steel components, carving wooden gunstocks, engraving both simple and elaborate designs on metal components, and applying finishes, Charles had no trouble keeping busy. He was also a locksmith, stencil cutter, and manufacturer of door- and nameplates. At his shop he sold ammunition, cartridges, powder flasks, shot bags, bowie knives, and other hunting goods.

There were no trade schools for teaching the skills Charles learned in Europe before he immigrated to the United States.

So how were these skills passed on?

In 1883 Charles took on a young apprentice, William H. Muhl, who was 12 at the time. Charles worked with William for 18 years, teaching him the many skills that he had learned.

When Charles retired in 1901, he sold his store to William, who continued to work as a gunsmith until his death in 1940.

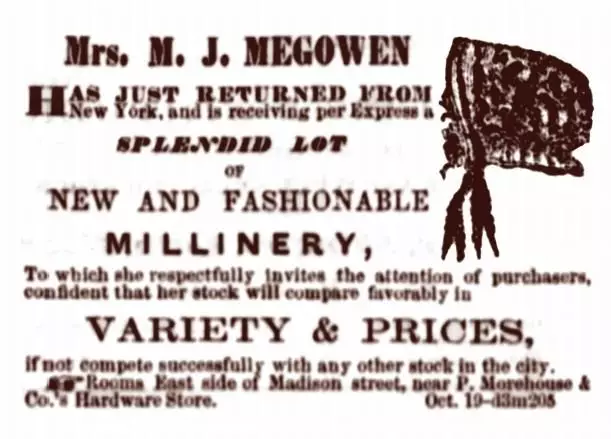

Mary J. Megowen

Mary J. Megowen Keith (dates unknown) was one of 33 dressmakers who hand-made clothing for Bloomington residents in 1855.

In her shop, located on Madison Street, Mary sewed for her customers “the latest Parisian fashions,” as well as practical garments. But her primary business was hats.

Mary sold her dress and hat shop to Miss Frank Essons in the fall of 1864, and moved to St. Louis where she opened a new shop.

She often returned to Bloomington with fancy goods to sell at her former shop.

One year later Mary returned to Bloomington with a new husband, Dr. Keith, and reestablished a millinery (hat) shop. She closed this shop and retired in 1870, shortly after she divorced Dr. Keith for being unfaithful and left town.

Gustave A. Wohlfeil

Gustave A. Wohlfeil (dates unknown) began work as a cutter and tailor for the W.P. Bolles Tailor Shop in 1895.

His job was to cut the pieces of fabric for both men’s and ladies’ garments, first tracing the shape of the pattern with tailor chalk, before cutting the fabric on those lines. Gus sometimes helped with the construction of garments by hand stitching collar interfacings and buttonholes, as well as sewing seams with one of the two sewing machines in the shop.

Frock coat, circa 1885

View this object in Matterport

This frock coat was custom made for Bloomington resident Fred Brown by a Bolles Tailor Shop employee.

Donated by: Alleice Van Ness Brown

814.1495

Bloomington had over 70 working tailors in 1897. By 1902 that number had dropped to nearly 40.

What would cause such a dramatic decrease?

Did Gus’ business survive?

By 1900 the number of stores selling quality, ready-made clothing, like Livingston’s, Klemm’s, My Store, and others, were cutting deeply into the custom clothing business. Gus closed his shop in 1902.

Factory work provided jobs that, with experience, enabled some people to start their own businesses.

In 1886 Christ Mandler (1858-1949) began to work at the Tryner and Richardson Cigar Company, one of the most successful cigar factories in Bloomington.

Christ already knew how to specially select, trim, and shape a variety of tobacco leaves, to create a wide range of cigars with subtle flavor and fragrance differences, as well as distinct sizes and shapes. He hand rolled and trimmed each one, then placed them inside a cigar mold so the finished cigar would have the proper shape when it dried.

After several years at the cigar factory, Christ began to think about setting out on his own. But knowing how to make a good cigar did not mean he was capable of running his own business.

If Christ asked your advice, would you have encouraged him to start his own business or to stay at Tryner & Richardson?

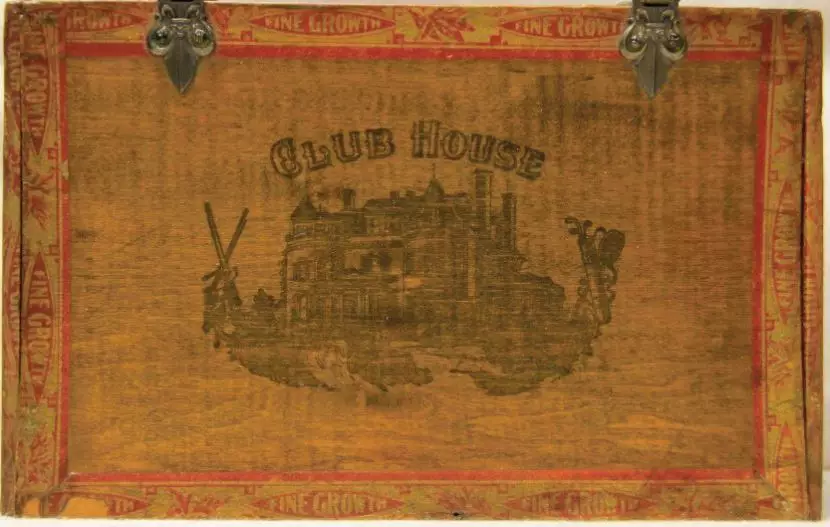

In 1891 Christ left Tryner & Richardson. He made his cigars in the basement of his home at 814 W. Olive Street. Every morning he left the house with two to three boxes of cigars under his arm. He walked (he never owned a car) to area taverns and special customers to sell and deliver the brands he created, such as “The Twins” (named for his son and daughter) and “The Club House.” Christ continued to hand roll all of his cigars, unlike other cigar makers who converted to mass produced machine-made cigars. At the height of his business, he hand rolled 1,500 to 2,000 cigars per week.

Christ retired in 1942 after 60 years of hand rolling over 4.5 million cigars.

Cigar humidor, hand-rolled cigars by Christ Mandler, circa 1900

Christ enjoyed smoking the custom cigars he made for himself, which he stored in this humidor — a special container that maintained the moisture level of the cigars. If a cigar got too dry, it was no good! The cigars inside this humidor were made by Christ.

Donated by: June Mandler McCluskey

2006.070.07, 08

Wooden cigar mold, circa 1885

View this object in Matterport

Donated by: Martin Wyckoff

728.61

Making a Home

Making a Home

A Community in Conflict

A Community in Conflict

Working for a Living

Working for a Living

Farming in the Great Corn Belt

Farming in the Great Corn Belt

Abraham Lincoln in McLean County

Abraham Lincoln in McLean County